Address: Building 1, Zone B, Wanyang Maker Town, Tingyao East Road, Jiashan County

Contact person: Guo Bo 15068353607

Telephone: 0573-84015258

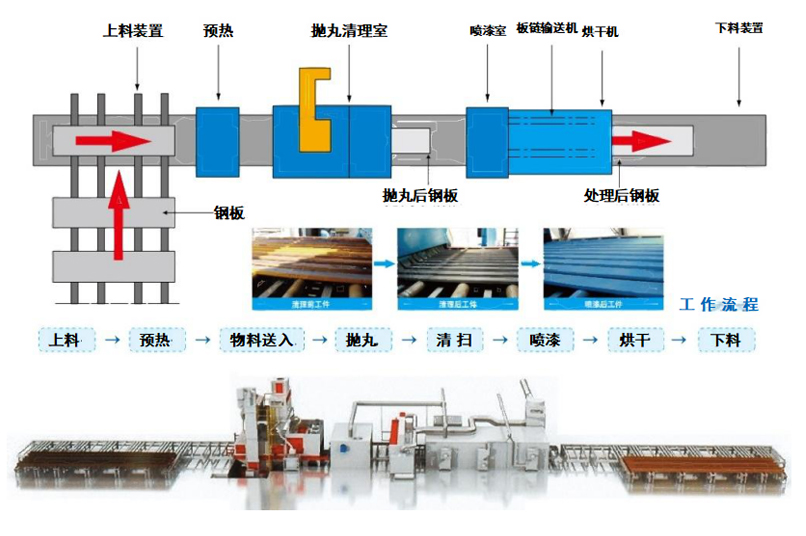

Structure:

The equipment mainly consists of input roller conveyor, preheating room, shot blasting cleaning room, transition roller conveyor, spray painting room, drying room, output roller conveyor, dust removal system, and electrical control system.

working principle:

This equipment is a high-efficiency continuous operation steel pretreatment production line. The steel is preheated through a roller conveyor and sent into the shot blasting cleaning room. Multiple high-efficiency shot blasting machines with different coordinate orientations use the pellets to exert strong and dense impact and friction on it, causing the oxide scale, rust spots, and dirt on its surface to quickly fall off, and the steel surface is cleaned and strengthened. During the shot blasting process, the scattered shot dust mixture is collected at the lower part of the elevator through the chamber funnel and longitudinal and transverse screw conveyors, and then lifted to the separator at the upper part of the machine for shot dust separation. The separated pellets fall into the separator hopper and are sent to each shot blasting machine for recycling through the pellet conveying pipeline. The dust generated during work is sent into the dust removal system through the exhaust duct, and the purified clean air is discharged into the atmosphere. The particulate dust is captured and collected by the dust collector.

After shot blasting, the steel is sent into the cleaning room, and the residual pellets on its surface are cleaned by a cleaning roller brush. Then, a high-pressure fan is used for all-round tail blowing, and the surface of the workpiece is cleaned thoroughly, meeting the cleanliness standards for painting. After cleaning, the workpiece is sent to the painting room, where two upper and lower painting machines are set up to spray paint on the workpiece. During the painting process, the thickness of the paint film can be adjusted and controlled by adjusting the roller running speed, nozzle size, and selecting the working mode. The steel after surface painting is sent to the drying room for drying treatment. The drying chamber adopts two methods: combustion heating or electric heating. After being dried in the drying room, the workpiece enters the conveyor roller at the discharge end, and finally completes the pre-treatment work of the steel.