Address: Building 1, Zone B, Wanyang Maker Town, Tingyao East Road, Jiashan County

Contact person: Guo Bo 15068353607

Telephone: 0573-84015258

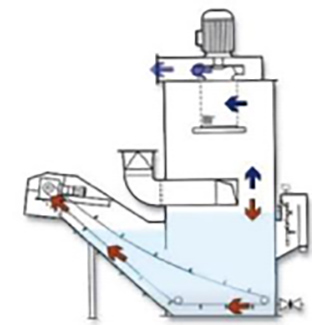

Principle description

The VT Venturi separator is designed using the high-efficiency Venturi principle. The airflow carrying smoke and dust needs to pass through a Venturi throat equipped with a washing liquid spray before entering the separator tangentially. The airflow rapidly accelerates at the Venturi throat, causing the liquid to vaporize. The relative motion of airflow and liquid causes thorough mixing, resulting in the accumulation of smoke or pollutants with droplets. In a high-speed centrifugal droplet separator, smoke droplets are separated from the airflow. The purified air is discharged from the central pipeline to the fan located on the clean air side. The separated sludge or pollutants are collected through corresponding methods according to their characteristics.

The biggest advantage

Strong universality; High separation efficiency; No secondary dust; Ultra low maintenance cost; No need for filter element or blockage; Compliant with atmospheric emission standards; Suitable for water containing and viscous dust; Space saving and modular design; Can remove a certain amount of water-soluble waste gas; Safely solve the problem of flammable and explosive dust removal; Suitable for high-temperature flue gas purification within a certain range; Integrated dust removal and desulfurization (regularly adding alkaline agents).

Application area

Carbon soil smoke and dust furnace, furnace ash, clay application, mixing station, tire production, cement manufacturing, mining, pigment production; Aluminum magnesium dust, drilling, sawing, forging, deburring, shaping, and finishing;

Viscous powder - pharmaceutical technology, food production, animal feed, pigment molding production, printing, adhesive, fabric shaping, mixing and conveying facilities; Steam and oil mist cleaning machine, die-casting, rolling mill, density board rolling, electroplating, waste disposal, etc;

Flammable and explosive dust grinding process, shaping, polishing, sandblasting, explosive production, grain processing, printed circuit board production, brake testing platform; Rubber/leather/plastic powder - shoe making, tire production, plastic processing, foil production, extrusion molding;

Fiber/fluff/fabric dust polishing process, waste sorting system, fabric processing, recycling factory, insulation material production, asbestos treatment.